Welcome

to Italy's

most advanced

predictive

maintenance

laboratory

Laboratory

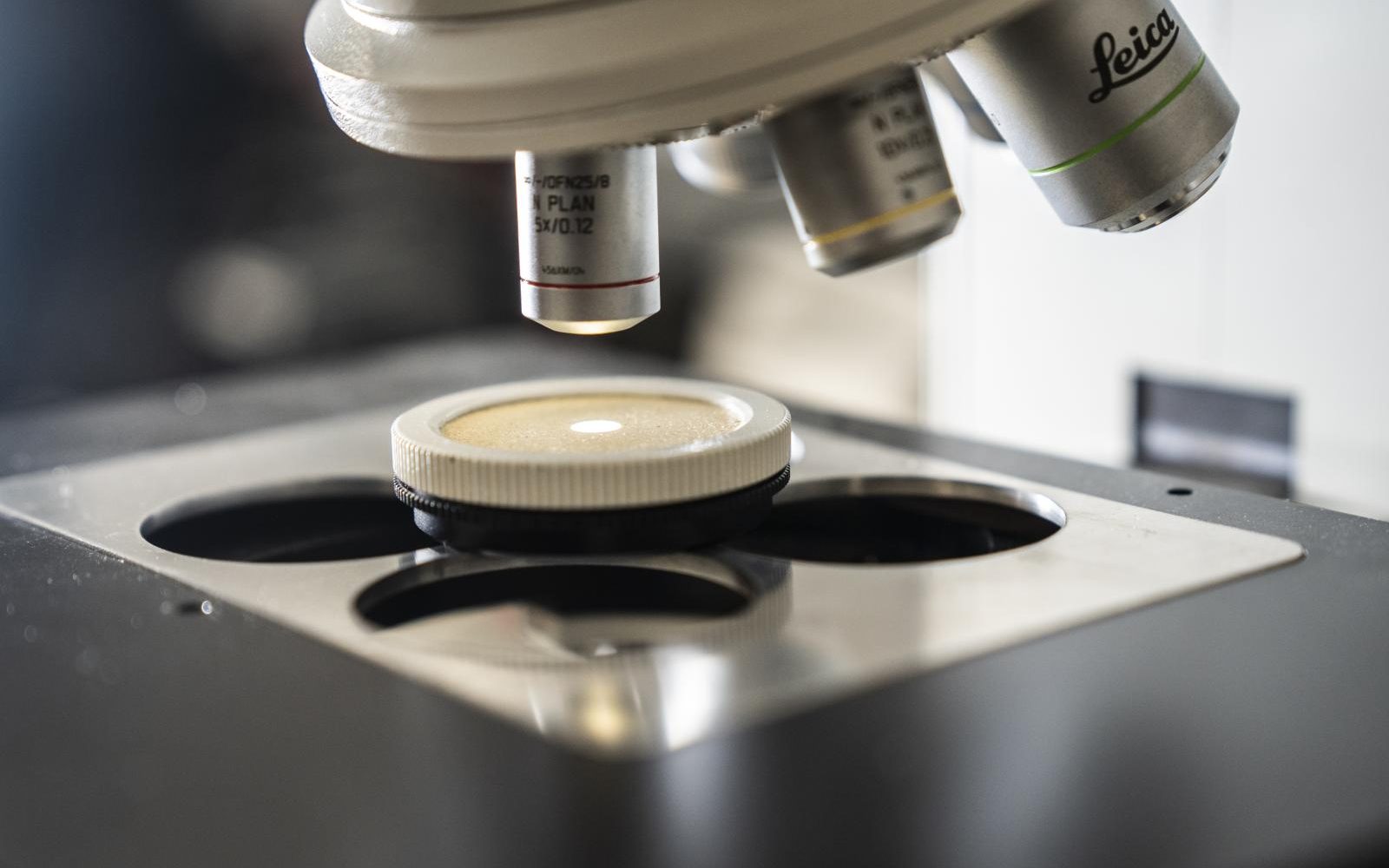

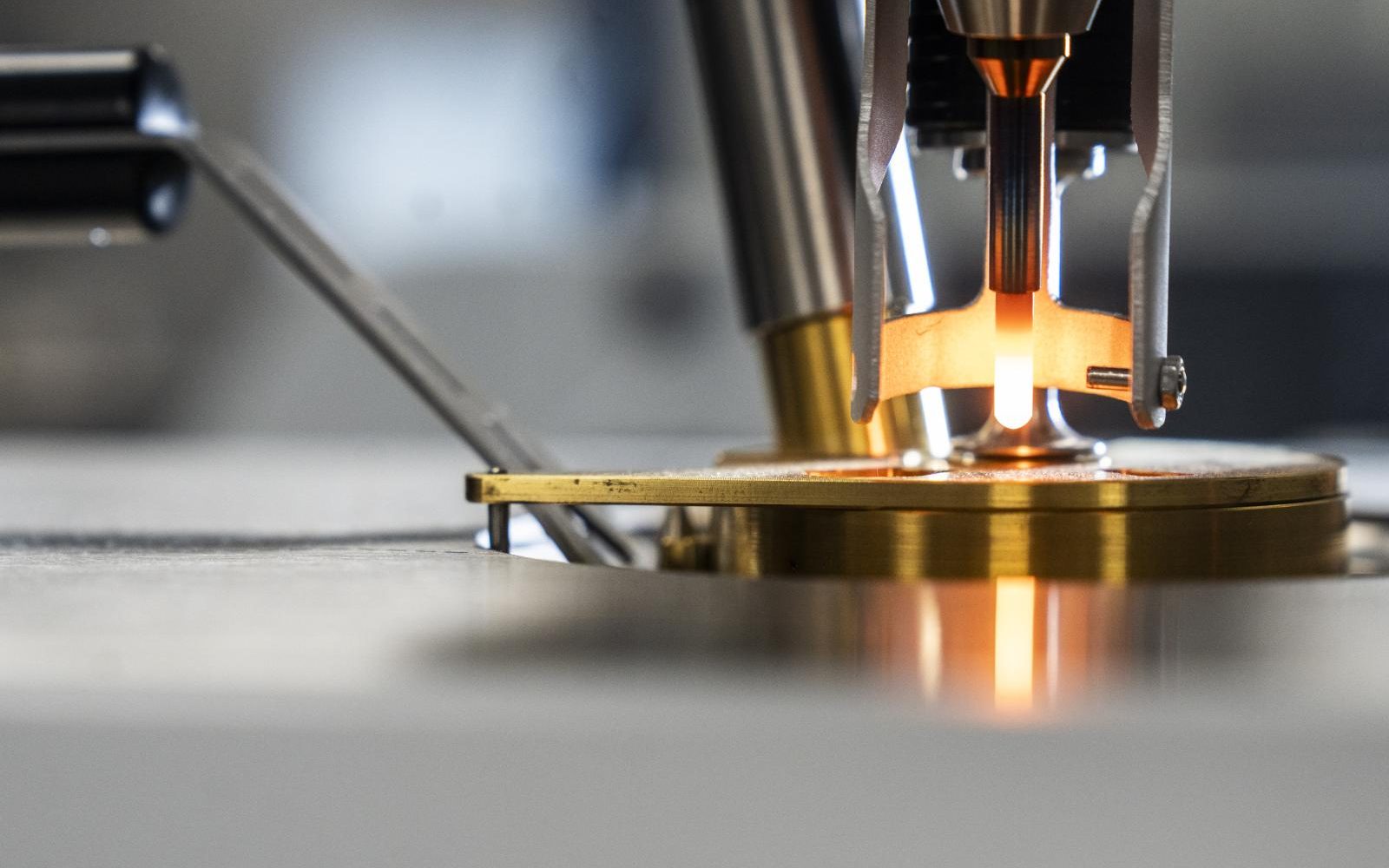

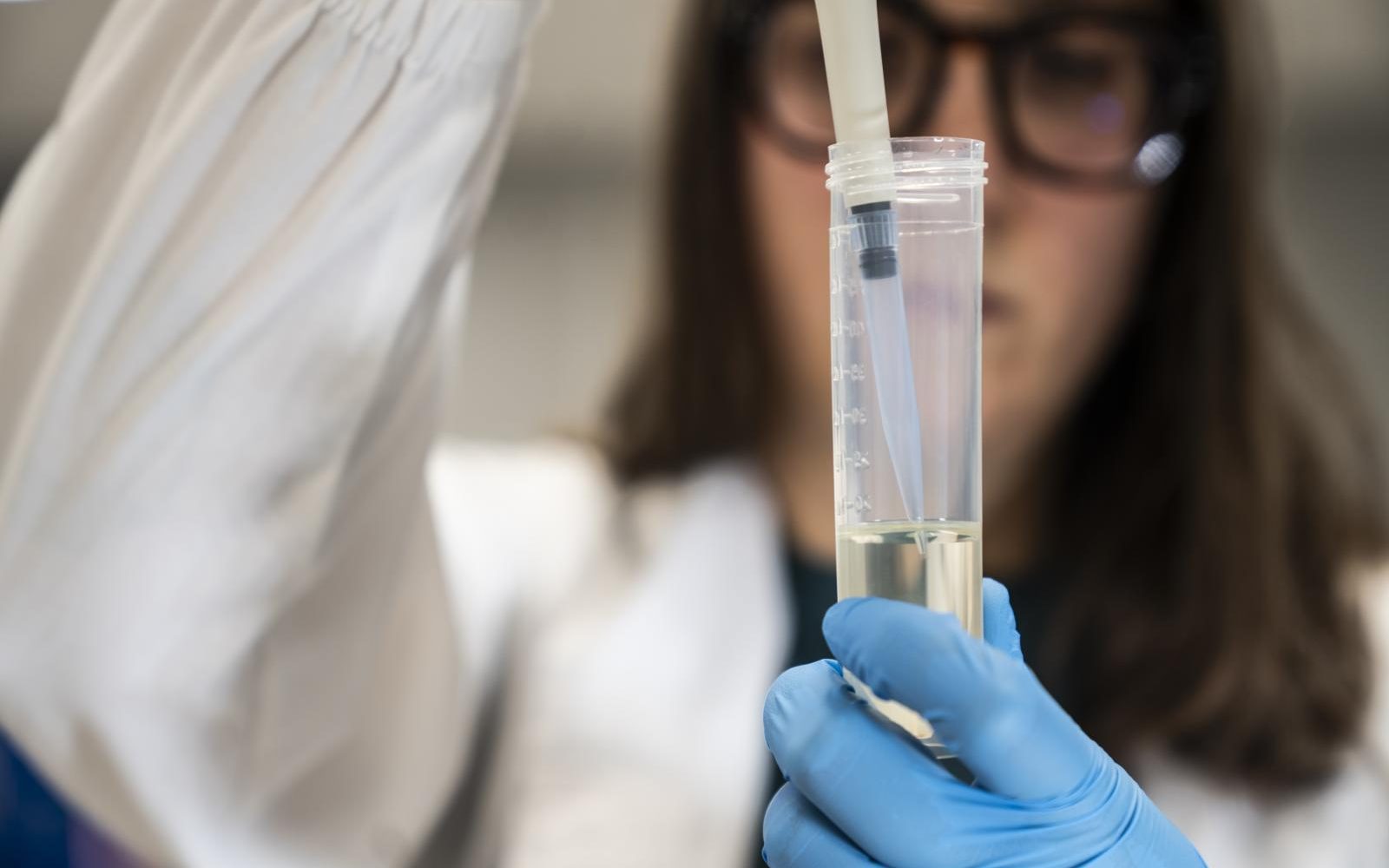

We scan the chemical-physical parameters of the oil and, through this, we identify potential issues that the machinery may be facing.

By analyzing the oil > we detect the contaminants present and the potential damage they could cause > We also determine how to remove these contaminants from the oil through proper analysis and filtration > extending the oil’s lifespan by five times and even preserving the machinery parts themselves. This approach helps reduce waste and minimize the environmental impact.

For Filtration, it is possible to reduce energy consumption by 4.35% with clean oil.

Our 24/7 Sensors. No more production downtime thanks to our sensors that introduce a new concept of 24/7 oil monitoring, utilizing the most advanced technologies and supported by a service package that include:

Never

without it.

Always connected = zero downtime

Reduce costs, stored spare parts, emergency interventions, and injuries, buy and dispose of less oil

Savings = higher margin

on the sale price of your products

3. Less oil = less waste

More health for your business and the environment. Thanks to proper maintenance, the oil you have can be sufficient for your company, today and tomorrow, without the constant need for new resources

No more machine downtime: always connected with our sensors.

24/7 monitored sensors mean there’s no need to wait for periodic analysis to know if something is wrong with the oil.

The sensores:

Internally produced, branded Gatti Filtrazioni Lubrificanti, and installed, maintained, and monitored by our qualified staff.

Installed directly on all industrial machinery that uses hydraulic oils, turbine oils, lubricating oils, and gear oils. Non-invasive and compact, they are applied on the outside of the systems.

Monitored 24/7, continuously, to provide real-time readings of oil cleanliness, water presence, and temperature.

Connected to a dedicated router, provided and installed by us: the company preserves its connectivity and operational efficiency.

Thanks to the daily data collection and storage, they track the oil’s evolution and retain data for 12 months

They detect anomalies in real-time and send live alerts to our laboratory, operations center, and the customer, enabling an immediate and automatic intervention process.