Scheduled

Periodic

Analysis

Analysis

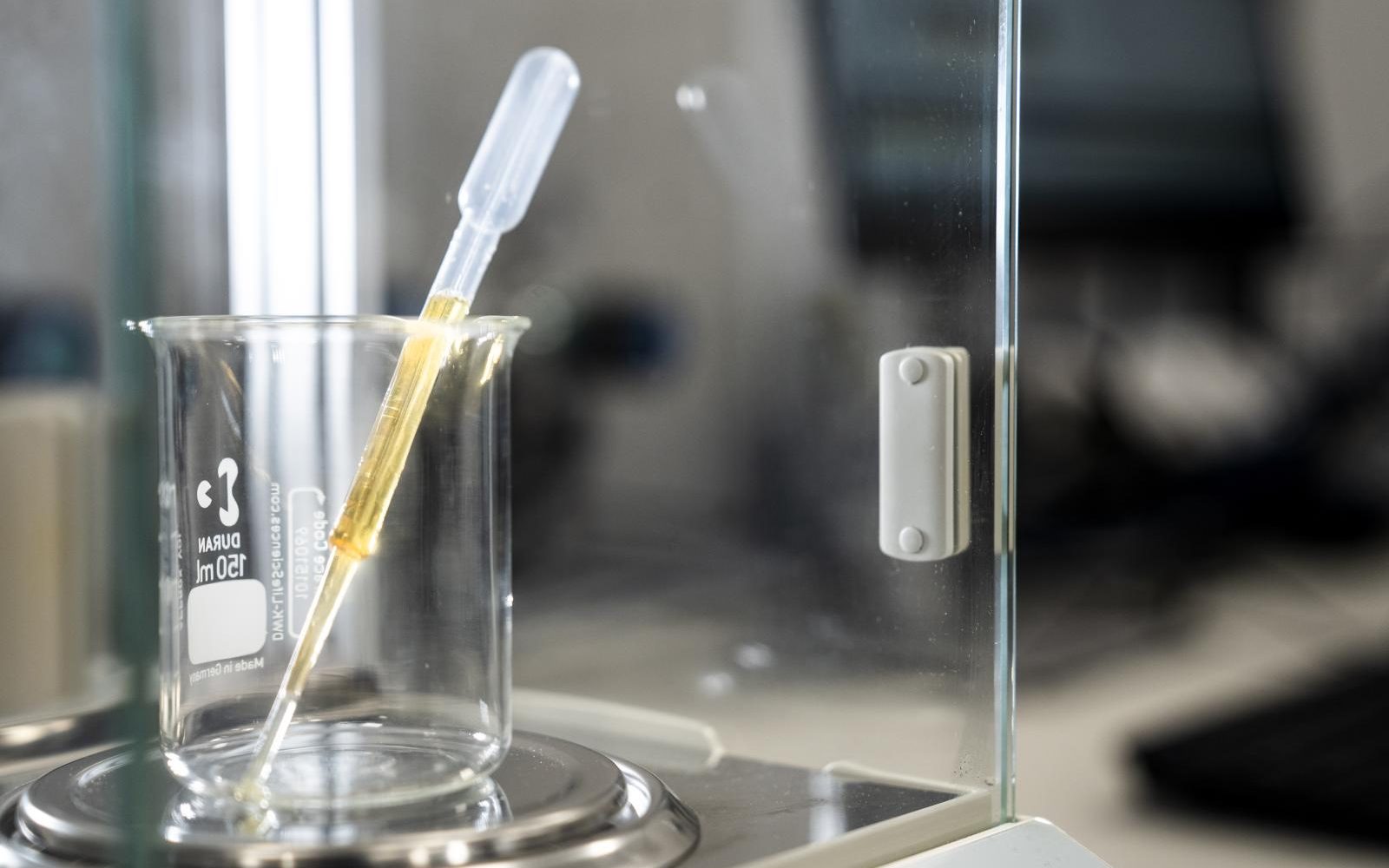

Thanks to periodic oil analyses every 3-6-12 months, your company can manage oil monitoring with peace of mind, automatically scheduling predictive laboratory analyses well in advance, ensuring optimal productivity at all times.

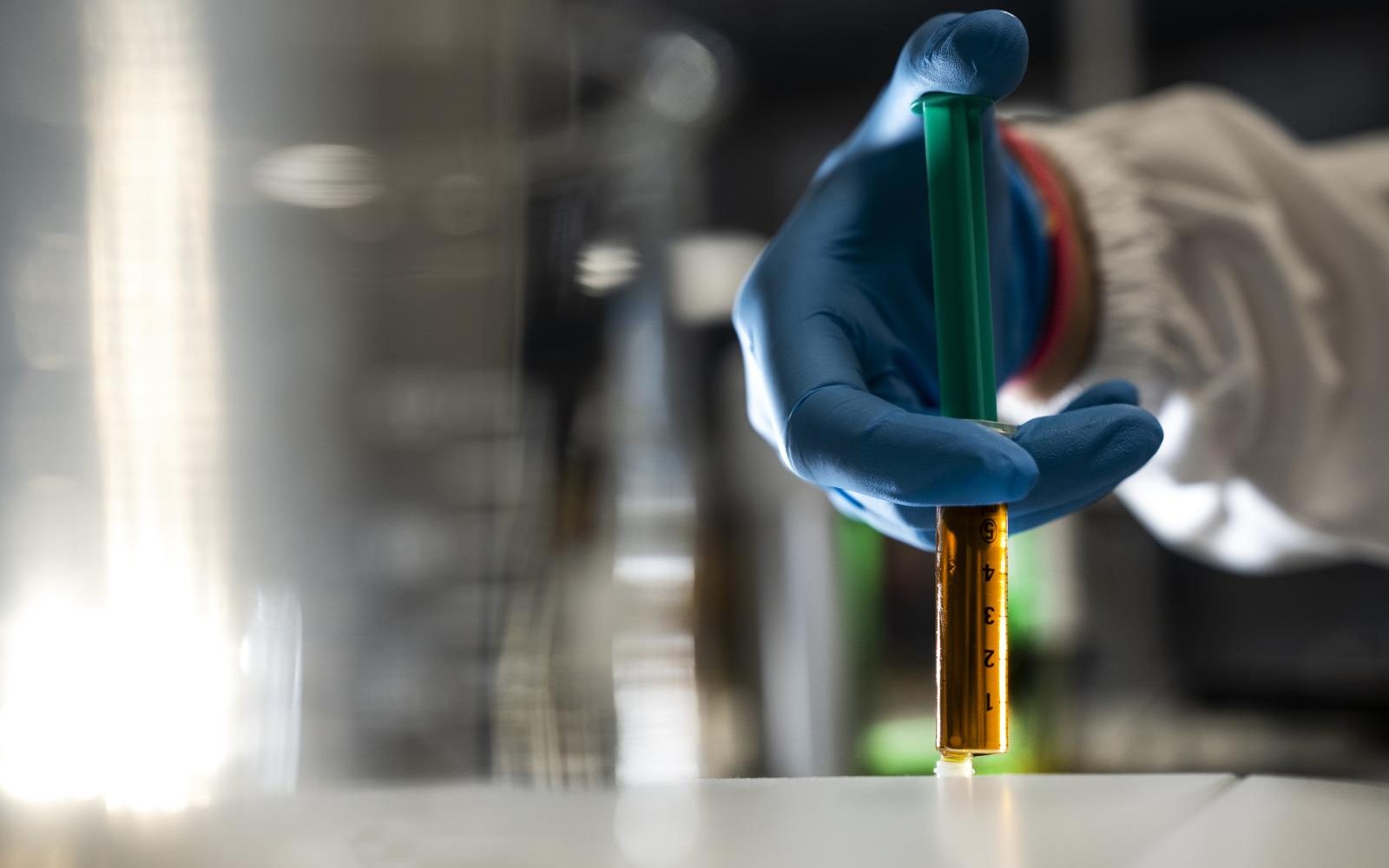

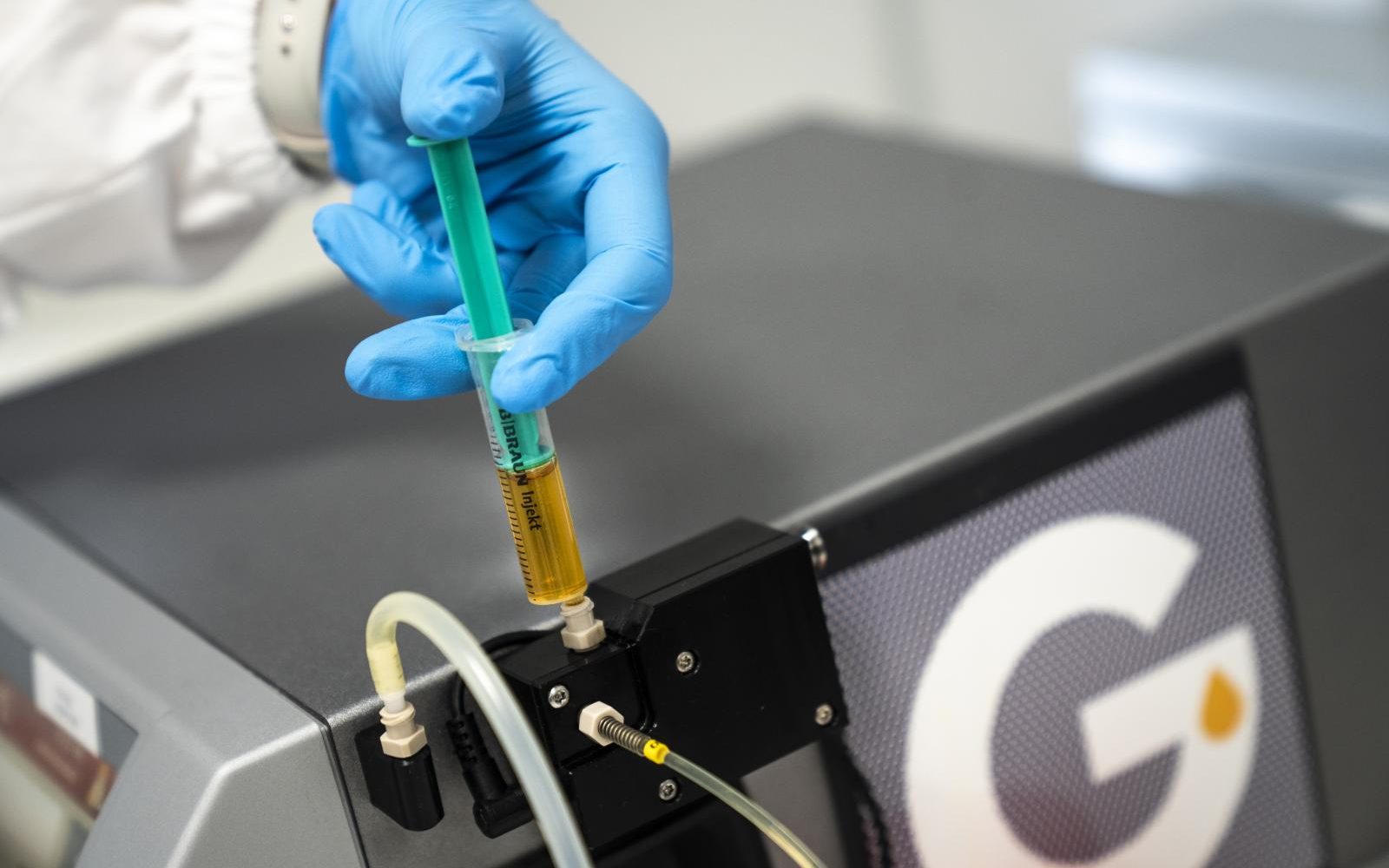

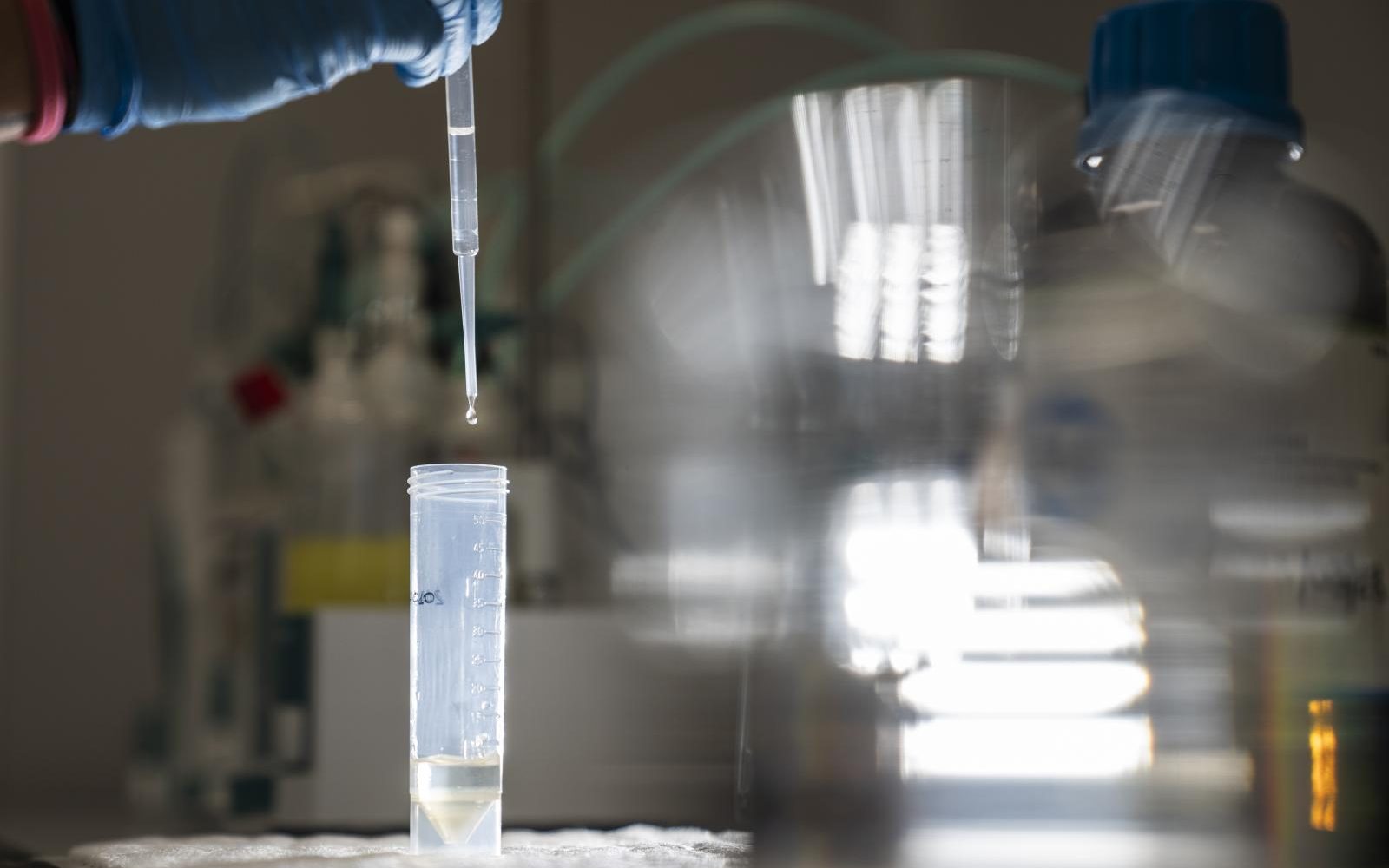

It is a thorough inspection that carefully examines the lubricant inside the machinery, allowing you to precisely determine the “health status” of the oils in use. This type of analysis breaks down the chemical-physical properties of the lubricant and, if present, any contaminants, in order to understand the operational conditions of the oil and, consequently, the overall condition of the system.

1

Automatically receive a notification from the system one week before the analysis deadline, allowing you to schedule a visit from one of our technicians for oil sample collection or prepare and ship the samples independently. You can collect the oil using dedicated vacuum-sealed containers, tracked with barcodes, and send the data to our laboratory via the app. Simple, as easy as a click.

2

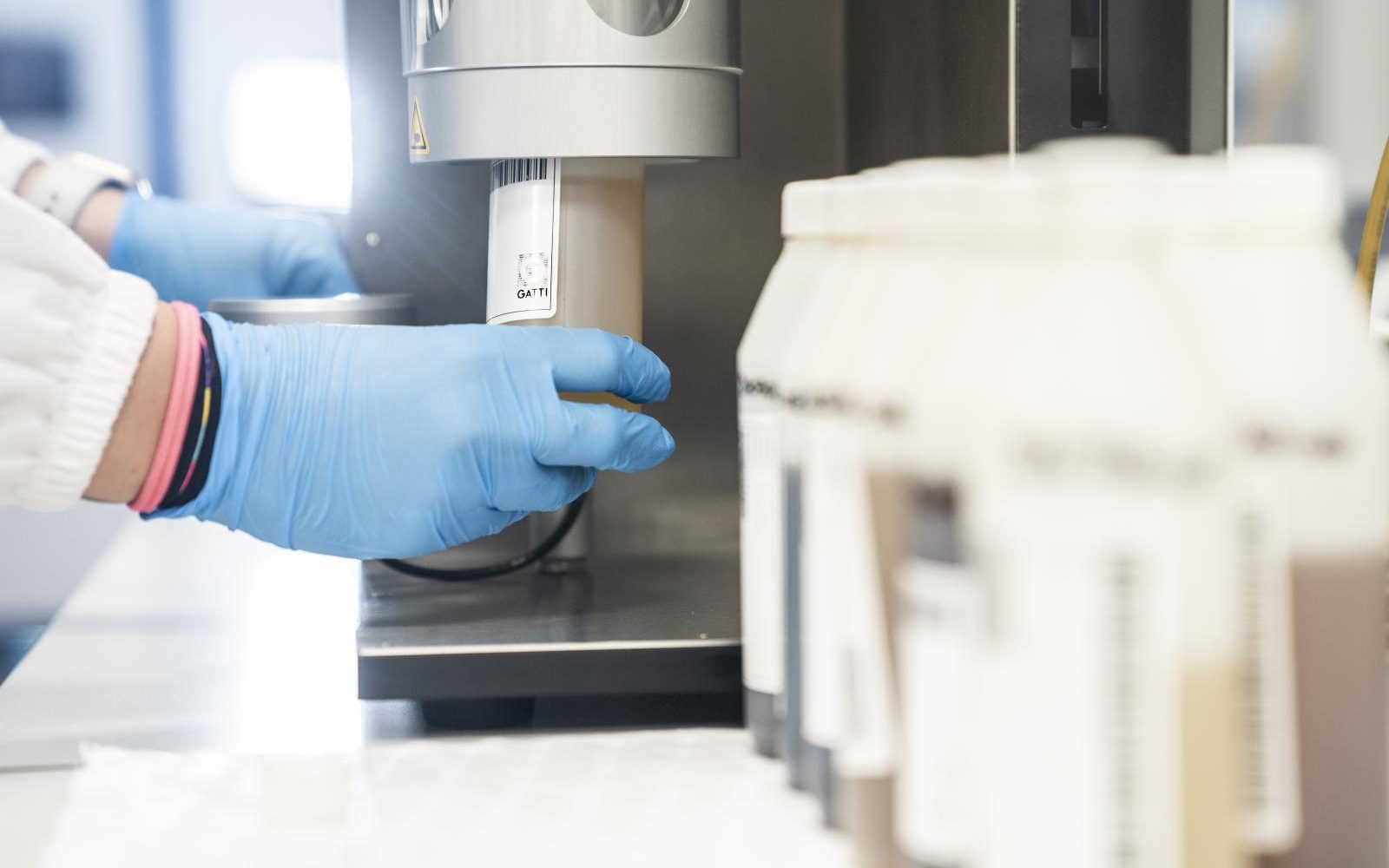

Know at any time, with full transparency and accuracy, the status of your sample: when it was received, if it’s being processed, and when the report is ready. If necessary, our operations center will quickly schedule an intervention.

3

View and download analysis reports at any time.

Which oils do we monitor with scheduled analysis?

HYDRAULIC OIL

Hydraulic oils can be categorized as follows:

- Mineral-based oils: Currently the most commonly used in hydraulic systems,

- Synthetic water-based fluids: Used when high flame resistance is not a strict requirement. Before use, it is essential to ensure compatibility with equipment, seals, hoses, and coatings,

- Non-aqueous synthetic fluids: Provide high fire safety while retaining some positive characteristics of mineral oils (such as lubricating properties, low pour point, and low vapor pressure at normal operating temperatures).

| Code | Type of Analysis | Code | Type of Analysis |

|---|---|---|---|

| 0257 | SET 1 | 0047 | SET 2 |

| Appearance | Appearance | ||

| Color | Color | ||

| Odor | Odor | ||

| Density | Density | ||

| Viscosity 40°C | Viscosity 40°C | ||

| Viscosity 100°C | Viscosity 100°C | ||

| Viscosity index | Viscosity index | ||

| Water content KF | Water content KF | ||

| Contamination Class (laser) | Contamination Class (laser) | ||

| Total Acid Number TAN | Total Acid Number TAN | ||

| Additives (Ca, Mg, Zn...) | |||

| Contaminants (Si, Na, B...) | |||

| Wear Metals (Fe, Cr, Sn...) | |||

| Infrared Spectrum (IR) | |||

LUBRICATING OIL AND GEAR OIL

The most appropriate choice depends on the operating conditions:

- Mineral Oils: Ideal for gearboxes that are not heavily loaded, with intermittent usage cycles and without significant temperature variations,

- Synthetic Poly-Alpha-Olefin Oils (PAO): Suitable for heavy-duty operations, with heavily and continuously loaded gearboxes that cause temperature increases,

- Synthetic Poly-Glycol Oils (PG): Should be used with great caution, as they are not compatible with other oils but are miscible with water, which can lead to rapid degradation. Recommended exclusively for applications involving significant sliding between contact surfaces.

LUBRICATING OIL

| Code | Type of Analysis | Code | Type of Analysis |

|---|---|---|---|

| 0314 | SET 3 | 0860 | SET 4 |

| Appearance | Appearance | ||

| Color | Color | ||

| Odor | Odor | ||

| Density | Density | ||

| Viscosity 40°C | Viscosity 40°C | ||

| Viscosity 100°C | Viscosity 100°C | ||

| Viscosity index | Viscosity index | ||

| Water content KF | Water content KF | ||

| Contamination Class (laser) | Contamination Class (patch test) | ||

| Total Acid Number TAN | Total Acid Number TAN | ||

| Additives (Ca, Mg, Zn…) | Additives (Ca, Mg, Zn…) | ||

| Contaminants (Si, Na, B…) | Contaminants (Si, Na, B…) | ||

| Wear Metals (Fe, Cr, Sn..) | Wear Metals (Fe, Cr, Sn..) | ||

| Infrared Spectrum (IR) | Infrared Spectrum (IR) | ||

| 3D Particle Analysis | 3D Particle Analysis | ||

| MPC TEST | MPC TEST | ||

| Gravimetry | Gravimetry | ||

| Closed Cup Flash Point | |||

GEAR OIL

| Code | Type of Analysis | Code | Type of Analysis |

|---|---|---|---|

| 0325 | SET 1 | 0258 | SET 2 |

| Appearance | Appearance | ||

| Color | Color | ||

| Odor | Odor | ||

| Density | Density | ||

| Viscosity 40°C | Viscosity 40°C | ||

| Viscosity 100°C | Viscosity 100°C | ||

| Viscosity index | Viscosity index | ||

| Water content KF | Water content KF | ||

| Contamination Class (patch test) | |||

| Total Acid Number TAN | Total Acid Number TAN | ||

| Additives (Ca, Mg, Zn...) | |||

| Contaminants (Si, Na, B...) | |||

| Wear Metals (Fe, Cr, Sn...) | |||

| Infrared Spectrum (IR) | |||

TURBINE OIL

The main challenges of gas and steam turbine oils are viscosity, oxidation, and thermal stability. High-performance turbine oils are made from Group III base fluids, which offer excellent wear protection and oxidation stability.

| Code | Type of Analysis | Code | Type of Analysis |

|---|---|---|---|

| 0250 | SET 1 | 0326 | SET 2 |

| Appearance | Appearance | ||

| Color | Color | ||

| Odor | Odor | ||

| Density | Density | ||

| Viscosity 40°C | Viscosity 40°C | ||

| Viscosity 100°C | Viscosity 100°C | ||

| Viscosity index | Viscosity index | ||

| Water content KF | Water content KF | ||

| Contamination Class (laser) | Contamination Class (patch test) | ||

| Total Acid Number TAN | Total Acid Number TAN | ||

| Additives (Ca, Mg, Zn…) | Additives (Ca, Mg, Zn…) | ||

| Contaminants (Si, Na, B…) | Contaminants (Si, Na, B…) | ||

| Wear Metals (Fe, Cr, Sn..) | Wear Metals (Fe, Cr, Sn..) | ||

| Infrared Spectrum (IR) | Infrared Spectrum (IR) | ||

| Onsolubles in Heptane, Solide Residue | Onsolubles in Heptane, Solide Residue | ||

| 3D Particle Analysis | |||

| MPC TEST | |||

| Gravimetry | |||

| Code | Type of Analysis | Minimum quantity |

|---|---|---|

| 0327 |

RULER ANALYSIS Measures the residual presence of antioxidant additives to determine the remaining lifespan of the lubricant |

50 ml |

| 0328 |

AIR RELEASE ANALYSIS A test to evaluate the ability of the lubricant to release trapped air bubbles |

400 ml |

| 0329 | FOAM FORMATION ANALYSIS 1 CYCLE | 200 ml |

| 0330 |

FOAM ANALYSIS 3 CYCLES Two tests for measuring the formation of surface foam in the lubricant |

400 ml |

| 0331 |

DEMULSIBILITY ANALYSIS Assesses the ability of the lubricant to separate water |

100 ml |

| 0332 |

RPVOT ANALYSIS A test to verify the oxidation stability of the lubricant |

100 ml |

| 0854 |

MPC TEST ANALYSIS Measures the tendency of the lubricant to form sludge and varnish |

100 ml |

WATER-GLYCOL (HFC FLUIDS)

Water-glycol-based fluids are composed of glycols and poly-glycols dissolved in water, enriched with anti-wear, anti-corrosion, and anti-foam agents. These fluids also contain water-soluble polymers that thicken the water, giving it viscosity characteristics similar to those of mineral oils. They are commonly used in hydraulic systems near heat sources, such as machinery for die casting, injection molding, manipulators in steel and glass production, and forging presses.

| Code | Type of Analysis | Code | Type of Analysis |

|---|---|---|---|

| 0250 | SET 1 | 0827 | SET 2 |

| Appearance | Appearance | ||

| Color | Color | ||

| Odor | Odor | ||

| Viscosity 40°C | Viscosity 40°C | ||

| pH (pH-metro) | pH (pH-metro) | ||

| % Water content (KF) | % Water content (KF) | ||

| Total Alkalinity | Total Alkalinity | ||

| % Surface Oil | % Surface Oil | ||

| Contamination Class (patch test) | Contamination Class (patch test) | ||

| Gravimetry | Gravimetry | ||

| 3D Particle Analysis | |||