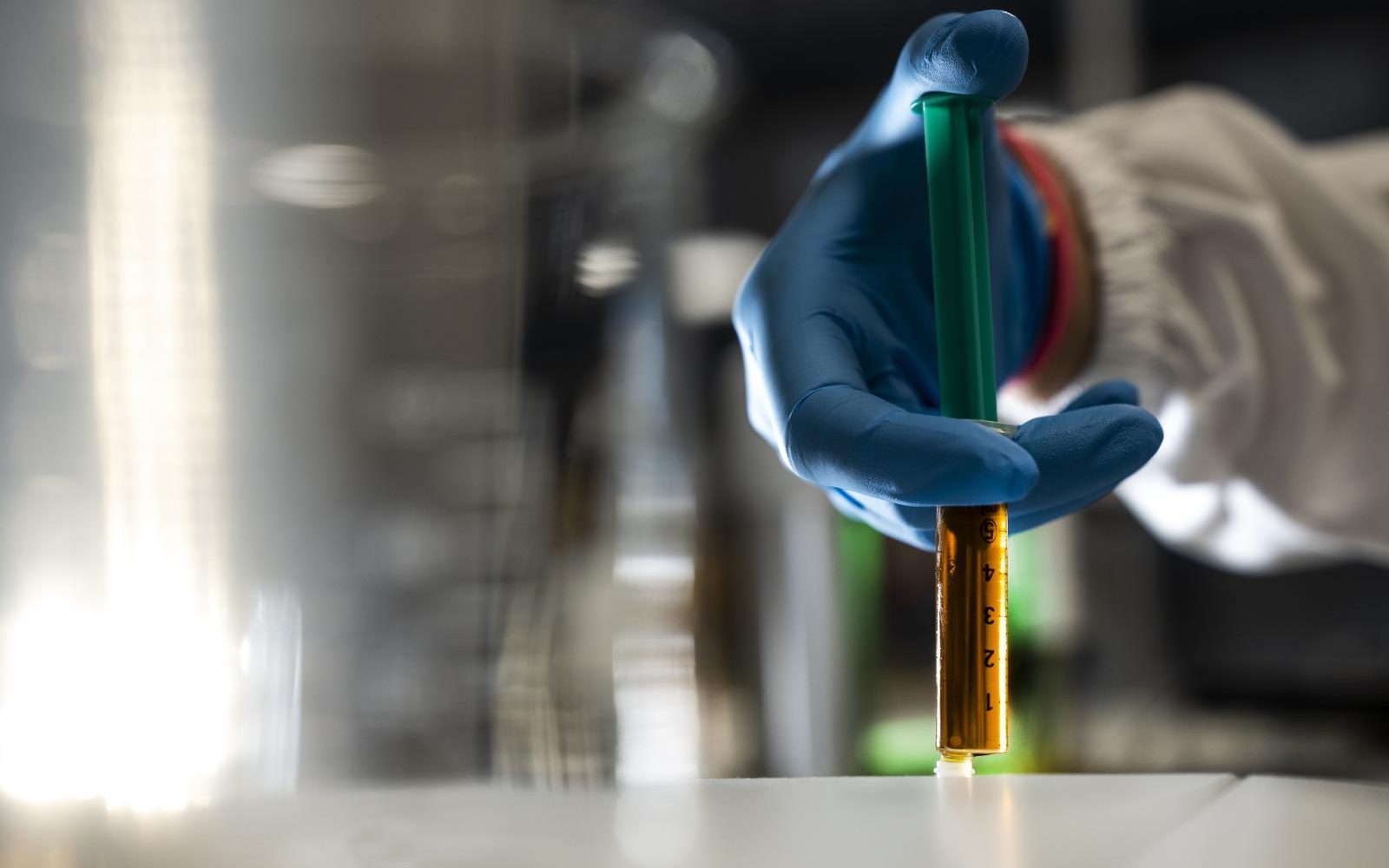

A reliable partner

for the analysis,

filtration and

management

of lubricating oils.

We enhance your company's performance, reduce your costs, and increase the productivity of your equipment, ensuring greater profitability.

Analysis

We have the

numbers to support

your business.

machines

available

for service.

available

for service.

0

million and 40

liters of oil

filtered in 2024

liters of oil

filtered in 2024

0

km of pipes

flushed

in 2024

flushed

in 2024

0

clients

served

in 2024

served

in 2024

0

hours average

response time

for assistance

response time

for assistance

0

macchine

disponibili

in service.

disponibili

in service.

0

News

Not just a company, but a unique technological and educational hub.

Thank you to Giornale di Brescia for the article “Not just a company, but a unique technological and educational hub,” which highlights our commitment…

Gatti Filtrazioni Lubrificanti one step ahead: the future is now

Gatti Filtrazioni Lubrificanti continues to push the boundaries of innovation, integrating advanced technology and artificial intelligence to enhance performance. It is from this vision…

Innovation and Sustainability in Coolant lubricant management

We are excited to present two cutting-edge products for coolant management and filtration in the mechanical processing sector: the Monitoring EM and the DFA…